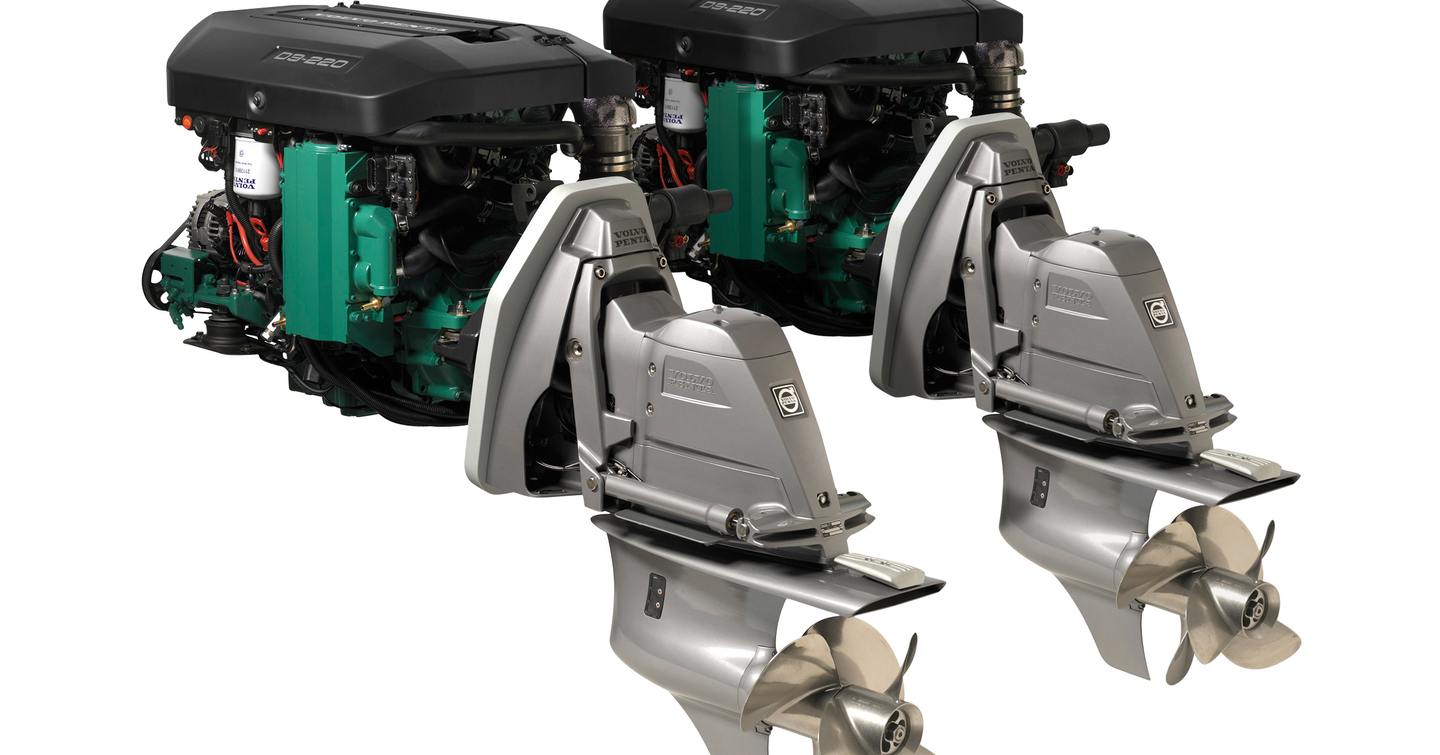

Sterndrive legs have a reputation as being expensive to run and maintain, but they are also widely acknowledged as the most efficient form of fast propulsion. With thousands currently in operation, what is the real sterndrive story?

When compared to a shaftdrive setup, a sterndrive leg is more complex, with more working parts outside of the yacht exposed to the saltwater environment. Many of these parts are important pieces of engineering that, if allowed to fail, can be expensive to replace.

At the same time, there is plenty of evidence to show that sterndrive legs and their various mechanisms are also extremely durable. As with almost every facet of yacht ownership, the trick to avoiding large costly invoices is regular checks and maintenance.

Why do Sterndrives Have a Bad Reputation?

When it comes to sterndrives, the term 'user error' is often mentioned. Sterndrives are not inherently unreliable or classed as bad, but if you do not maintain the drive unit then be prepared for some nasty surprises.

Poor maintenance will always have its repercussions, but when it comes to sterndrives, salt or raw water ingress can be potentially fatal for the componentry.

If water is allowed to get through one of the drive seals and into the internal gear housing, disaster can strike. Seals cost pennies, and regular servicing is not as expensive as replacing an entire drive solution. So, service regularly, replace the seals, and your sterndrive should enjoy trouble-free running.

The Economic Option?

Sterndrives represent an economic power installation for yacht builders, being easy to fit and offering good performance for their given horsepower. This is then passed on to the buyer as a lower-priced yacht that is fun to drive while delivering relatively good efficiency. A diesel engine sterndrive yacht is perhaps the most efficient option for fast cruising.

Careful and regular maintenance is the key to managing sterndrive running costs. Regular visual checks on key service areas, replacing parts when necessary, and sticking to annual service schedules will help to protect working parts while managing costs.

Daily Checks

One of the best ways to avoid expensive servicing costs is to keep an eye on the drive unit, regularly looking for specific signs of wear or failure. If any are found, act immediately. Whilst few of us visit our yacht every day, a quick weekly or monthly check will also help to alert you to a potential problem or an upcoming failure.

Bellows

The main seal for the drive, this rubber sleeve should be fairly pliable, securely fastened, and completely free of any tears.

If the bellows cracks or fails in any way, letting in salty air or water, it can quickly lead to serious mechanical issues.

Watertight Seals

Your sterndrive leg may have several seals, so check that each seal looks in good condition.

If your leg has seals around the hydraulic rams, check for growth on the ram itself as this can tear the seal during movement.

Anodes and Drive Casing

One of the most important visual checks is on the anodes. There will be several placed on the drive unit so make sure you know where they are. The anodes should perish over a period of time that depends on the level of electrolysis in the water and will need to be replaced at least every year. Once the anode is down to 25% you should plan to replace it.

If anodes perish or cannot offer adequate protection then corrosion will occur to the drive’s aluminium casing. Look for signs of pitting to the drive casing and paintwork as a sure sign that corrosion is happening.

Service Intervals

New Boats

For new yachts under warranty, servicing will be at regular pre-stated intervals and must be carried out by an approved engineer to maintain those warranties. The cost for this procedure will be labor only with any parts covered by the warranty. However, the cost of craneage (to lift a vessel out of the water) will not be covered.

Warranty Period

Most sterndrive warranties will be for two years or up to a certain number of hours. You may also have the option of extending the warranty for major components beyond two years. Volvo Penta offers a two-year or 600-hour period (whichever is shorter) plus the option to extend warranted cover against major mechanical parts for a further three years. It is also worth noting that warranties are usually transferable if there is a change of ownership.

Older Vessels

For all sterndrive vessels, an annual service is highly recommended. A more involved service is recommended every 2-3 years which involves the leg being removed and major service items including the various watertight seals being renewed.

But don’t worry about getting the work carried out, most marinas and ports will have local marine engineers on hand to carry out the required work.

Costs (non-warranty)

- Annual professional service costs around USD $630 per leg

- Two-year overhaul costs are highly dependent on replacement parts

- Engine service costs additional

- Yacht lift-out/craneage costs additional

Annual maintenance costs will vary depending on the make and model of the leg, but as a guide an annual service, carried out by an engineer, will be around USD $630 per leg. The cost of a full three-year service will vary hugely depending on what parts need replacing and so the amount of labor required.

As with any propulsion system service, the yacht itself will need to be lifted out of the water. This has as much to do with inspecting the hull and drive as carrying out the service.

Key Maintenance Areas

Key Outdrive Leg Service Areas:

- Anodes

- Outer leg casing

- Hydraulic arm seals

- Bellows

- Drive gear oil

- Impeller

It is also worth noting that key maintenance areas closely match up to visual checks.

Drive Casing and Anodes

The tilt mechanism of the sterndrive allows some of the leg to be lifted out of the water when moored, but the salt air and environment still have a corrosive effect.

The outer casing of the sterndrive is made from aluminum and requires cathodic protection from electrolysis (chemical decomposition produced by electrical currents passing through the water; salt or fresh). This is achieved using anodes, sacrificial blocks that corrode in place of the leg and which should be replaced regularly.

Note: an anode is meant to corrode, if it doesn’t, it means it is not doing its job and other, more expensive metal parts may be corroding instead.

Seals

As already mentioned, the hydraulic arms and the all-important universal joint that allows the engine to tilt and turn must be kept watertight. The bellows, the main watertight seal that protects the inner workings of the sterndrive and its gear housing, including the universal joint, must be checked regularly and replaced if any signs of perishing are evident. This might be every two or three years depending on use.

Impeller

The impeller draws and circulates raw cooling water. It cannot be easily checked but is cheap and easy to replace as part of a service.

Unlike a shaftdrive yacht, a sterndrive variant needs to be taken out of the water to replace the impeller

Sterndrive Gear Oil

It is worth replacing the sterndrive leg’s gear lube or oil every year. This is an important job as the fluid quality can alert you to a more serious issue. The drive fluid will turn a milky color if water has found its way into one of the seals. If you see this, you can immediately replace the seals and save yourself a far larger bill should the problem have gone unnoticed.