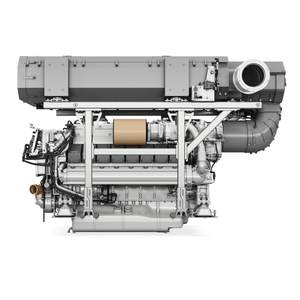

MTU Series 2000 Range

MTU's Series 2000 diesels are yet another example of how electronic engine management gives an added degree of operating flexibility.

Based on the same direct-injected four-stroke 90° vee design, the eight, 12 and 16-cylinder models all boast multi-turbo configurations with intercooling, four-valve heads and electronic engine management. The same 130mm cylinder bore and 150mm stroke is used throughout the range with a displacement of 1.99lt per cylinder and a low compression ratio of 15.2:1. Replaceable cast-iron wet cylinder-liners are used and the pistons have a chrome/ceramic coating. Unusually, the valves are located at the 'corners' of the combustion chamber with a central injector, supplied by individual injection pumps mounted on the cylinder block. Individual cast-iron cylinder-heads are considered to improve component access and reduce downtime. The Series 2000 crankcase is a single-piece unit of cast-iron and has integrated water and oil channels.

The crankshaft is forged steel with bolted-on counterweights. The exhaust lines are watercooled essential when the exhaust gas temperature, after leaving the turbocharger, is 500°C! The Series 2000 range is equally at home in tropical or cold climates. For example, according to MTU's own figures, even with a 45°C intake air temperature and 32°C seawater temperature the 8V 2000 M90, 12V 2000 M90 and 16V 2000 M90 models each lose only 1.5% of their rated crankshaft output. The latest higher-performance version of the 12V 2000, the M91 model, loses 3%.

Series 2000 Engines

Let us know any corrections or additions.