Yachts between 10m to 15m are usually equipped with a sterndrive, shaftdrive, or pod drive propulsion system. To help with the decision-making process, we have listed the main benefits of each drive system below.

For many years, shaftdrive propulsion was the only option for larger yachts of more than 10m (32ft). This was followed by stern or outdrive systems, an option for fast yachts of up to approximately 14m (46ft), resulting in enhanced performance with improved power-to-weight ratios.

Far more recently, pod drives arrived on the market. Designed as an alternative to shaftdrive, the system can be combined with a joystick control to deliver precise and intuitive close-quarter maneuverability. Before we dive into drive system comparison, however, let's begin with a major consideration.

The Impact on Interior Space

Whilst you might think a propulsion article should probably focus on performance, the demand for luxury and space onboard today’s yachts means that accommodation is often one of the biggest factors when selecting a propulsion system.

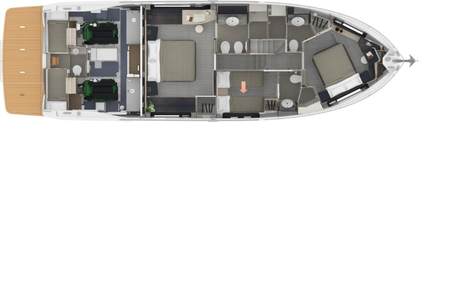

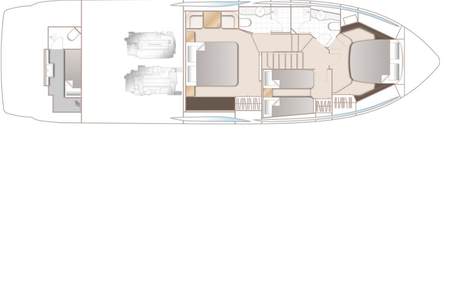

A conventional shaftdrive system will see the engines being installed close to amidships, taking up the central portion of a vessel; an area which also happens to be the most voluminous. The knock-on effect of the engines being located amidships — where a cabin would normally be found — places pressure on the remaining interior space, especially for vessels under 15m (49ft).

The square amidships section of a yacht is the ideal location for a private, quiet master cabin, and so by selecting a drive system that moves the engines to an alternative place onboard, yacht builders can have an increased amount of design flexibility.

Onboard larger yachts over 15m (49ft), the interior space can normally cater to different layouts, regardless of the engine and drive system.

Both sterndrive and pod drive systems site the engines aft, thus increasing the amount of interior space amidship for accommodation. For this reason, many yachts under 20m (66ft) will be equipped with these drive types to maximize space onboard.

There is also an ever-increasing number of larger horsepower pod drive solutions coming to market, enabling larger yachts to benefit from the more accommodating power option.

Shaftdrive

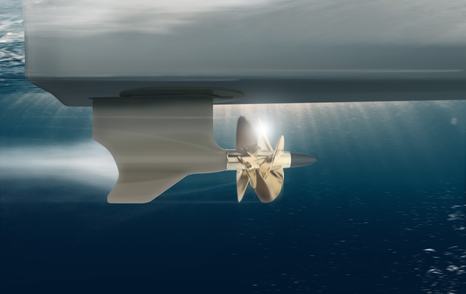

This drive system consists of an inboard engine and a gearbox connected to an aligned shaft. This shaft then runs through the hull to a supported propeller and a rudder for steerage.

Shaftdrive propulsion is as effective as it is versatile, providing reliable power delivery to all sizes and types of vessels, from 7m (21ft) dayboats to 24m (79ft) superyachts, all with differing hull designs.

The propeller and rudder arrangement gives good slow-speed handling and also precise feedback when traveling at speed. With a p-bracket supporting the shaft and a rudder outside of the hull, there are several large metal components in the water. This creates drag and reduces speed.

Efficiencies

Although sterndrive and pod drive systems are considered more efficient, a single shaftdrive setup running at a slow speed is hard to beat, both in terms of fuel usage and simplicity. However, as the number of faster yachts increases, twin installations are becoming more common. This effectively doubles the installation weight and the amount of drag, requiring more horsepower to hit higher speeds.

Maintenance

Whilst the installation of a shaftdrive engine requires more work on the part of the yacht builder, this is a simple and comparatively low-tech setup that requires relatively straightforward maintenance.

The engine and gearbox inside the hull, as with all options, will require regular servicing. There is also a watertight shaft seal or stern gland — where the shaft passes through the hull — which requires regular visual checks to ensure there is no water ingress.

For all of the drive types, it is what lies outside of the hull that requires the most attention and is most at risk of corrosion or damage.

A shaftdrive's exterior componentry consists of a shaft, p-bracket, propeller, and rudder. Due to the simplicity of the design, the running gear is normally only checked for signs of wear and tear as part of its annual service. If nothing is found, the drive solution will be cleaned to ensure it continues to operate correctly.

Cutlass Bearing

The exception to a shaftdrive's relatively maintenance-free service schedule is the so-called cutlass bearing. This sits inside the p-bracket and enables the shaft to spin freely. The bearing has no specific maintenance period, although it should be fine for several seasons. As a precaution, the shaft and bearing should be checked for excessive play each time the yacht is lifted out of the water. If required, the cutlass bearing can be replaced without removing the shaft for approximately USD $200.

Shaftdrive: At A Glance

Pros

- Central location offers good balance for the vessel

- Concise handling at all speeds

- Straightforward maintenance

Cons

- Less efficient and lower speeds when compared to equivalent drives

- Bigger engines to create higher performance means more expensive purchase price

Pod drive (inc. IPS)

The most recent evolution in yacht propulsion, the pod drive is as much about the user-focused technology it brings as the thrust it delivers.

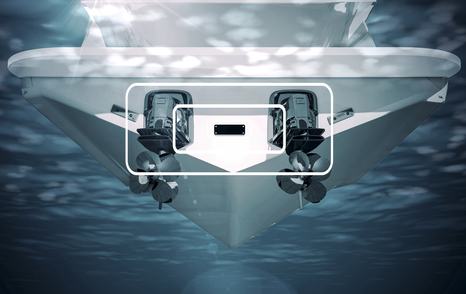

Developed in the commercial sector, particularly for ferries, multiple drives work independently of each other to deliver precise close-quarter maneuverability. Each external pod is driven by its own steerage motor which sits on top of the drive within the engine bay, with a large cushioned 'O' ring sealing the two sections.

Joystick Control

For leisure use, the pod drive is designed to be an alternative to shafts and is focused on planing yachts. Usually found in twin installations (but with triple and even quadruple packages available), traditional throttles are used to control each engine but with the electronic software managing and harnessing the independent steerage. A joystick control system can also be employed for a highly intuitive level of control for close-quarter maneuvers.

It is this close-quarter advantage that really appeals to owners, allied to functions such as the GPS-controlled dynamic positioning that holds a vessel in a stationary position and avoids the need or stress of trying to fight wind and tide as you wait for a fuel berth; or to simply get fenders in place.

The other main benefits of improved fuel economy and performance over shafts, by way of the more hydrodynamic pods, have resonated less. This may be down to costs. Pod drives can deliver the same level of performance as shafts but with smaller engines, however, any saving these smaller engines might bring is usually taken up with the cost of the joystick and other technology.

Forward Thinking?

A unique characteristic of some pod drives is a forward-facing design, with the propeller facing ahead. In all other drives, the propeller faces aft, pushing the yacht along. In this setup, it effectively pulls the yacht forward, and in doing so, also pulls the hull down for a more level trim angle.

Not all pod drives are forward-facing, in fact, only Volvo Penta's IPS (Independent Propulsion System) design is, but it's also by far the most common and popular variant of the pod drive. IPS was one of the earliest, if not the first pod drive for leisure use, and has become the face of pod drive technology and design. Mercury's Zeus system also arrived on the market around the same time but has aft-facing propellers.

The level trim experienced on pod-drive yachts, and especially IPS, allows a planing hull to operate at its optimum angle, for both ride quality and efficiency. Level trim does not mean no lift, the hull design still produces lift as speed increases, but the hull can maintain its design angle and poise, with its finer, forward section cutting through the waves. The opposite of this would be where the stern of the yacht digs in, the bow rises up and the resulting ride is harsh, as the flatter mid-ship sections hit the waves.

Maintenance

As with any sophisticated machinery, there is the danger of added maintenance or cost. However, the sealed pod drive unit is fairly well insulated against the rigors of saltwater and so doesn't suffer the same issues as sterndrives.

Permanently submerged, the outer casing does need to have careful cathodic protection with anodes replaced regularly; and certainly every season. If the anodes reduce quickly the pods can corrode, resulting in costly repairs. With drives exposed under the yacht, there were concerns over damage caused by debris or nets, but this concern does not seem to have materialized.

Pod Drive: At A Glance

Pros

- Joystick control for easier close-quarter maneuvering

- Precise handling at speed

- Joystick control for easier close-quarter maneuvering

Cons

- Smaller engines than shaftdrive but little saving on yacht price

- Pod drive leg requires careful maintenance

Sterndrive

The inboard sterndrive engine offers responsive handling at high speed, backed up by good economy. A single diesel sterndrive yacht is perhaps the most efficient set-up out there, with a slippery leg allied to an economic powerplant. A twin sterndrive setup, however, is not far behind in terms of efficiency.

The drive itself is basically a gearbox hanging from the transom, connected to the inboard engine by way of a universal joint that enables the drive to move laterally for steerage, but also vertically.

Control and Trim

This ability to trim a sterndrive leg up and down allows the helmsman to tune the legs to suit the speed and conditions. Trimming in gives more grip, assists moving onto the plane, and brings the bow down; useful in a head sea. Trimming the legs out reduces not only the drag of the legs but also the hull itself, with the extra angle of the legs pushing the hull up and out of the water.

If handled correctly, sterndrives offer excellent slow-speed maneuverability too. Adding power and steerage delivers immediate and direct course changes. However, the legs offer little steerage without power and this can lead to some stressful moments, especially if too much power is added in a confined area.

Sterndrives represent an economic power installation for yacht builders, being easy to fit and offering good performance for their given horsepower. This is then passed on to the buyer as a lower-priced yacht that is fun to drive with relatively good efficiency.

Maintenance

When compared to a shaftdrive, a sterndrive leg is more complex, with more working parts outside of the yacht and so exposed to the saltwater environment. Many of these parts are important pieces of engineering that, if allowed to fail, can be expensive to replace. If maintained correctly though, sterndrive legs and their various mechanisms can be reliable.

Sterndrive: At A Glance

Pros

- Good performance and efficiency for a given HP

- Efficiency allows for smaller engines and so lower yacht purchase cost

- Tilt and trim system for precise high-speed handling when used correctly

Cons

- Higher levels and cost of maintenance

- More complicated slow-speed handling

Shaftdrive vs Pod drive vs Sterndrive

Away from the central matter of interior accommodation, the shaftdrive starts to make plenty of sense, and for highly practical reasons too. This is due to its central location creating a very neutral and balanced vessel, delivering a comfortable ride. However, each drive has its advantages and disadvantages when it comes to performance, handling, and maintenance.

| Drive Type: | Pros | Cons |

|---|---|---|

|

Shaftdrive |

The central location offers a good balance for the vessel. Concise handling at all speeds. Straightforward maintenance. |

Less efficient and lower speeds when compared to equivalent drives. Bigger engines to create higher performance means a more expensive purchase price. |

|

Pod Drive |

Precise handling at speed. Joystick control for easier close-quarter maneuvering. |

The pod drive leg requires careful maintenance. Smaller engines than shaftdrive but little saving on yacht price. |

|

Sterndrive |

Good performance and efficiency for a given HP. Efficiency allows for smaller engines and lower yacht purchase costs. Tilt and trim system for precise high-speed handling when used correctly. |

Higher levels and cost of maintenance. More complicated slow-speed handling. |